In today’s competitive business environment, small and medium enterprises (SMEs) often face the challenge of achieving big dreams with limited resources. Lean management techniques can be the secret weapon that helps you eliminate waste, streamline processes, and boost productivity, all while keeping costs under control.

Dynamic Capabilities Consulting (DCC) recently had the opportunity to share insights in the article by Dynamic Business “Lean hacks for SMEs: Maximise productivity on a budget,” exploring how lean management can transform businesses. Due to word limits, we couldn’t cover everything in the article, so here are additional key points and actionable strategies to help your SME thrive.

Understanding Lean Management

Lean Warning Label: Contains common sense.

Lean management is all about getting the most out of what you have by cutting out the waste. Imagine focusing solely on what your customers need and streamlining your processes to meet those needs perfectly. For small and medium enterprises (SMEs), this approach isn’t just a nice-to-have—it’s often the key to not just surviving but truly thriving in today’s competitive market.

Key Principles of Lean Management

Here’s a brief overview of its core principles and techniques:

- Value Stream Mapping: Identify and map out the steps that deliver your product or service to the customer. Eliminate any steps that do not add value.

- Continuous Improvement: Foster a culture where your team continuously identifies inefficiencies and suggests improvements.

- 5S System: Implement the 5S system – Sort, Set in order, Shine, Standardise, Sustain – to maintain an organised and efficient workspace.

- Technology Integration: Leverage technology to automate repetitive tasks and use project management tools to keep everyone aligned.

Practical Lean Techniques for SMEs to Get Started

Implementing lean management techniques can seem daunting, but it doesn’t have to be. By breaking down the process into manageable steps, small and medium enterprises (SMEs) can begin to see tangible benefits quickly. In this 3 stage approach to lean, we’ve broken down practical, actionable strategies that SMEs can apply to start their lean journey. From understanding customer needs to mapping out current processes and identifying waste, these techniques are designed to help you streamline operations and maximise productivity, all while keeping costs under control.

As most people have been to a bakery at some stage, we’ll provide examples for a bakery business along the way.

Start Your Lean Journey Right: Align with Business and People

Before getting started on a journey to implementing lean management, it’s critical to ensure you bring others along on the journey.

Internal Stakeholders: Engage with all internal stakeholders (employees, managers, and executives) to ensure alignment and buy-in for the process.

Internal Stakeholders: Engage with all internal stakeholders (employees, managers, and executives) to ensure alignment and buy-in for the process. Employee Involvement: Involve employees at all levels in the process to gain insights from those who perform the tasks daily and to foster a sense of ownership.

Employee Involvement: Involve employees at all levels in the process to gain insights from those who perform the tasks daily and to foster a sense of ownership. Communication: Maintain open and transparent communication throughout the process to ensure everyone understands the goals and benefits of value stream mapping.

Communication: Maintain open and transparent communication throughout the process to ensure everyone understands the goals and benefits of value stream mapping.

Stage 1: Understanding Value

Know Your Customer Needs and Expectations.

Before making changes, it is critical to understand what your customer needs and expectations are to start with. Without these insights, there is a risk that changes will have a negative impact on customers and the business. Additionally, consider your internal team as customers: take the time to understand their needs and expectations as well.

1. Conduct Surveys, Interviews, and Feedback Sessions

![]() Surveys: Create simple online surveys to gather customer opinions. Ask what they like about your product or service, what they think could be improved, and what they consider most important. Example: The bakery sends out a short online survey to its customers, asking questions like: “What’s your favourite item?”, “What would you like to see more of?”, and “How can we improve your experience?”.

Surveys: Create simple online surveys to gather customer opinions. Ask what they like about your product or service, what they think could be improved, and what they consider most important. Example: The bakery sends out a short online survey to its customers, asking questions like: “What’s your favourite item?”, “What would you like to see more of?”, and “How can we improve your experience?”.

Interviews: Talk directly to a few customers. This can provide deeper insights into their needs and preferences. Example: The bakery owner talks to a few regular customers to get deeper insights. One customer says they love the fresh bread but wish there were more gluten-free options.

Interviews: Talk directly to a few customers. This can provide deeper insights into their needs and preferences. Example: The bakery owner talks to a few regular customers to get deeper insights. One customer says they love the fresh bread but wish there were more gluten-free options.

Feedback Sessions: Hold regular feedback sessions, either online or in person, where customers can share their thoughts and experiences. Example: The bakery holds a monthly feedback session and/or competition with a prize where customers can drop in and share their thoughts. Customers highlight that they value the bakery’s friendly service and fresh products but dislike long waiting times.

Feedback Sessions: Hold regular feedback sessions, either online or in person, where customers can share their thoughts and experiences. Example: The bakery holds a monthly feedback session and/or competition with a prize where customers can drop in and share their thoughts. Customers highlight that they value the bakery’s friendly service and fresh products but dislike long waiting times.

2. Identify Key Features and Quality Aspects

From the data collected, identify the features that customers mention most frequently. Understand the quality and service aspects they prioritise. For instance, is speed more important than detailed customisation? Is reliability more valued than price? By understanding these points, you can focus on what truly matters to your customers and deliver better value.

Example: Customers frequently mention the freshness of the bread and the friendly service. They also value quick service and would like more variety in gluten-free products.

3. Understand Value-Adding Activities

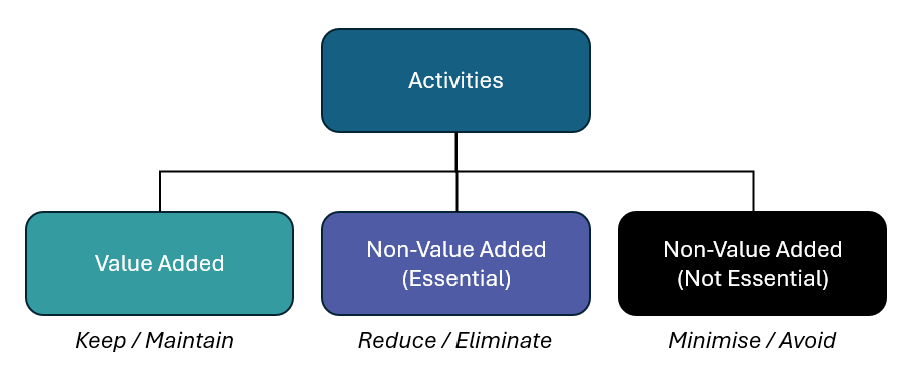

Now that you have context of key features, quality aspects and what is important to customers, distinguish the difference between Value-Adding and Non-Value-Adding activities.

![]() Value-Adding Activities – These are actions that directly contribute to fulfilling customer needs and expectations. For example, assembling a product, providing a service, or delivering customer support that solves problems effectively.

Value-Adding Activities – These are actions that directly contribute to fulfilling customer needs and expectations. For example, assembling a product, providing a service, or delivering customer support that solves problems effectively.

Example: Baking fresh bread and pastries every morning. Serving customers with a smile and helping them choose products. Introducing new gluten-free options based on customer feedback.

![]() Non-Value-Adding Activities – These are actions that do not directly add value and can be considered waste. Examples include excessive paperwork, waiting times, redundant inspections, or unnecessary movement of materials. Focus on maximising value-adding activities while minimising or eliminating non-value-adding ones.

Non-Value-Adding Activities – These are actions that do not directly add value and can be considered waste. Examples include excessive paperwork, waiting times, redundant inspections, or unnecessary movement of materials. Focus on maximising value-adding activities while minimising or eliminating non-value-adding ones.

Example: Excessive time spent on bookkeeping during peak hours. Redundant quality checks that don’t catch actual issues. Waiting for the next batch of dough to rise without doing other preparatory work.

Some non-value adding activities are still necessary. Understanding what value adding activities need to be maintained is critical. A more critical approach should be taken to non-value adding activities based on whether they are essential or not, and therefore avoided or reduced where possible or eliminated altogether.

Stage 2: Understanding the Current State

Know your current state to design the optimal future.

1. Mapping the Current State

To improve, you first need to understand your current process. Lean uses value stream mapping, however there are many ways to document a process. Below is an example of a value stream map for a business on a page, at a high level. Breaking these down into the different processes and tasks for Stamping, Assembly and Shipping in the below example will provide the level of detail needed to identify wastes and improvement opportunities.

Process Documentation:

Document every step involved in delivering your product or service. Start from the moment an order is received to the point of delivery. Include every action (E.g. processing orders), decision point (E.g. quality checks), and handoff (E.g. transferring a product from one department to another).

Example: The bakery documents all steps from opening the shop, preparing dough, baking, setting up displays, serving customers, to closing the shop. This includes every action, like mixing ingredients, and every decision point, like checking if the dough has risen enough.

2. Identifying Waste

Identifying and eliminating different types of waste is key to streamlining your process. Use the map of the current state process to identify different types of waste that occur at different stages. There may be one or multiple types of waste occurring within different steps of the process.

Identify The Different Types of Waste (TIMWOOD):

Transport: Unnecessary movement of products or materials. (E.g. unnecessary movement of ingredients from storage to the baking area.)

Transport: Unnecessary movement of products or materials. (E.g. unnecessary movement of ingredients from storage to the baking area.) Inventory: Excess products or materials that are not needed immediately. (E.g. keeping too many baked goods that end up not being sold and wasted.)

Inventory: Excess products or materials that are not needed immediately. (E.g. keeping too many baked goods that end up not being sold and wasted.) Motion: Unnecessary movement of people. (E.g. staff walking back and forth between the front counter and the kitchen unnecessarily.)

Motion: Unnecessary movement of people. (E.g. staff walking back and forth between the front counter and the kitchen unnecessarily.) Waiting: Delays between process steps. (E.g. customers waiting too long for their orders during peak hours.)

Waiting: Delays between process steps. (E.g. customers waiting too long for their orders during peak hours.) Overproduction: Producing more than what is needed. (E.g. baking more bread than needed, leading to wastage.)

Overproduction: Producing more than what is needed. (E.g. baking more bread than needed, leading to wastage.) Overprocessing: Doing more work or using more resources than necessary. (E.g. spending too much time on decorative finishes that customers don’t really value.)

Overprocessing: Doing more work or using more resources than necessary. (E.g. spending too much time on decorative finishes that customers don’t really value.) Defects: Errors that require rework or result in scrap. (E.g. bread that doesn’t rise properly and needs to be discarded.)

Defects: Errors that require rework or result in scrap. (E.g. bread that doesn’t rise properly and needs to be discarded.)

Document the different occurrences of waste and understand why they occur by looking into the root causes.

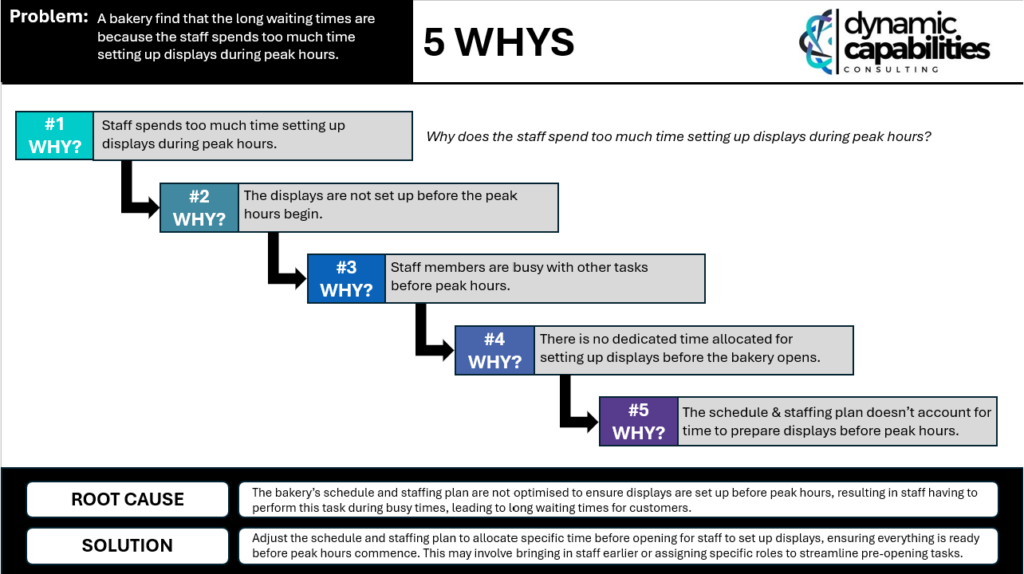

3. Analyse the Root Causes

By understanding the root causes of wastes, you can address the underlying issues rather than just the symptoms. Use tools like the 5 Whys (asking “why” five times to get to the root cause of a problem) or the Fishbone Diagram (a visual tool to identify potential causes of a problem).

- Example: They find that the long waiting times are because the staff spends too much time setting up displays during peak hours. By asking “why” multiple times, they realise this is because displays are not pre-arranged the night before.

(Free download available from our Templates)

Stage 3: Implementing A Leaner Future.

Map your path from current to future state.

Once you have a map of the current state and understand the root causes of waste, mapping out what the future process looks like is important to see where the points of difference would be, and who is impacted. By having a current and future state process outlined, you can easily see where the differences between the current and future state exist and where action needs to be taken to implement changes.

1. Mapping Future State

Ideal Process Flow: Using the current state map, design a future state map that eliminates or reduces any non-value-adding activities identified. Streamline the processes to improve flow and reduce bottlenecks.

Ideal Process Flow: Using the current state map, design a future state map that eliminates or reduces any non-value-adding activities identified. Streamline the processes to improve flow and reduce bottlenecks.  Improvement Strategies: Develop strategies for continuous improvement, such as implementing pull systems, reducing batch sizes, or improving workflow layouts.

Improvement Strategies: Develop strategies for continuous improvement, such as implementing pull systems, reducing batch sizes, or improving workflow layouts.

2. Implementing Changes

Turning the future state map into reality can seem daunting. Start by breaking down the implementation steps and testing out changes to ensure they’re going to be effective and achieve the desired results.

Action Plan: Create a detailed action plan outlining steps, responsibilities, and timelines for implementing the improvements identified in the future state map.

Action Plan: Create a detailed action plan outlining steps, responsibilities, and timelines for implementing the improvements identified in the future state map. Pilot Testing: Start with pilot tests on a smaller scale to ensure changes are effective before rolling them out company-wide.

Pilot Testing: Start with pilot tests on a smaller scale to ensure changes are effective before rolling them out company-wide.

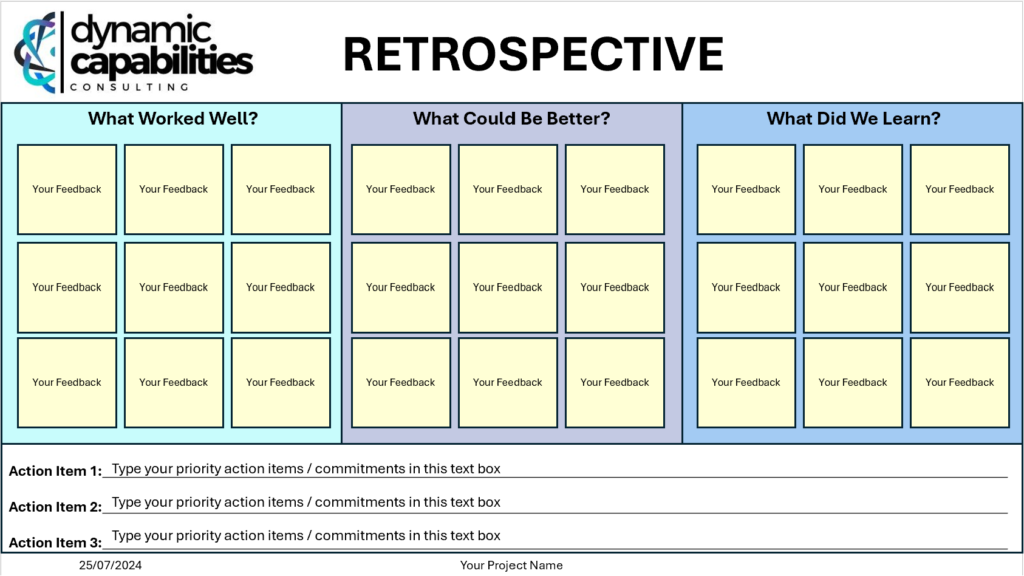

3. Continuous Monitoring and Improvement

Its important to review performance and gather feedback on an ongoing basis to find out what is working well, what further opportunities exist to improve and prioritise the changes to implement. The philosophy of continuous improvement and lean principles drives a focus on small incremental changes to make further improvements. Small changes mean risks are more controlled, so that the impact of changes are able to be tracked to the new variables. Introducing too many changes, big or small, is not only overwhelming, but makes it difficult to discern what changes are having a positive or negative impact.

Performance Metrics: Establish key performance indicators (KPIs) to monitor the impact of changes and ensure they are delivering the expected improvements.

Performance Metrics: Establish key performance indicators (KPIs) to monitor the impact of changes and ensure they are delivering the expected improvements. Feedback Loops: Set up regular feedback loops with employees and customers to gather input on the changes and identify further opportunities for improvement. A few key performance indicators will help gauge the progress and impact of changes so that tweaks can be made progressively. Team retrospectives is one way to achieve this.

Feedback Loops: Set up regular feedback loops with employees and customers to gather input on the changes and identify further opportunities for improvement. A few key performance indicators will help gauge the progress and impact of changes so that tweaks can be made progressively. Team retrospectives is one way to achieve this.  Training and Engagement: Ensure that all employees are trained in lean principles and engaged in the continuous improvement process. Encourage a culture where everyone is committed to identifying and eliminating waste.

Training and Engagement: Ensure that all employees are trained in lean principles and engaged in the continuous improvement process. Encourage a culture where everyone is committed to identifying and eliminating waste.

(Free download available from our Templates)

Focusing on these steps, any business, even those new to these concepts, can begin to implement lean management techniques and improve their efficiency and customer satisfaction. This way, businesses can ensure that their value stream mapping efforts effectively align with customer needs, streamline their processes, and engage their people, leading to sustained improvements in efficiency and productivity.

Embracing lean management doesn’t require a large budget or extensive resources. It’s about making smart, informed decisions to enhance efficiency and add value. By understanding your processes, identifying waste, and continuously seeking improvements, your SME can thrive in a competitive market.

DCC’s Commitment to Supporting Small and Medium Enterprises (SMEs)

At Dynamic Capabilities Consulting, we empower businesses to create inclusive, compliant, and efficient workplaces. Partner with us to unlock the full potential of lean management for your SME.

Book a Free Consultation and discover how we can help you:

Boost Productivity: Streamline processes to maximise efficiency.

Boost Productivity: Streamline processes to maximise efficiency. Reduce Costs: Identify and eliminate waste to save resources.

Reduce Costs: Identify and eliminate waste to save resources. Enhance Customer Satisfaction: Align your offerings with customer needs.

Enhance Customer Satisfaction: Align your offerings with customer needs. Foster Continuous Improvement: Build a culture of ongoing innovation and excellence.

Foster Continuous Improvement: Build a culture of ongoing innovation and excellence.

Don’t let limited resources hold your business back. Take the first step towards a leaner, more productive future. Book your free consultation today.